MW

Matt Wright

@mattwright.bsky.social

Restaurant owner in Austin, dad, hoops fan. Main interests: #rstats, data viz, Power BI, cheaper housing, Wem-V-P. (Not a frequent poster.)

165 followers598 following313 posts

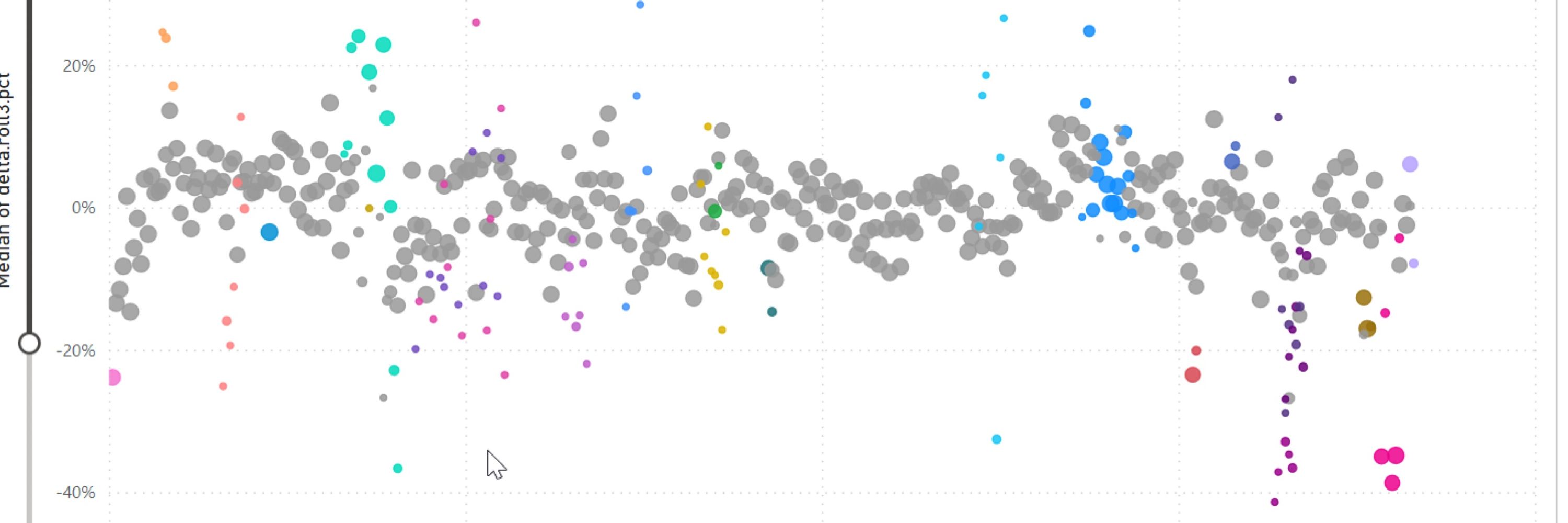

Oh wow. Did not realize it took that long to bring penicillin to mass production. The push to have it available for the invasion of Normandy sounds like an Oppenheimer sequel waiting to happen.

![On March 14, 1942, the first patient was treated for streptococcal sepsis with US-made penicillin produced by Merck & Co.[97] Half of the total supply produced at the time was used on that one patient, Anne Miller.[98] By June 1942, just enough US penicillin was available to treat ten patients.[99] In July 1943, the War Production Board drew up a plan for the mass distribution of penicillin stocks to Allied troops fighting in Europe.[100] The results of fermentation research on corn steep liquor at the NRRL allowed the United States to produce 2.3 million doses in time for the invasion of Normandy in the spring of 1944. After a worldwide search in 1943, a mouldy cantaloupe in a Peoria, Illinois market was found to contain the best strain of mould for production using the corn steep liquor process.[101] Pfizer scientist Jasper H. Kane suggested using a deep-tank fermentation method for producing large quantities of pharmaceutical-grade penicillin.[102][26]: 109 Large-scale production r](https://cdn.bsky.app/img/feed_fullsize/plain/did:plc:mcirit3dx4qo3xhjli3wsy6n/bafkreih7oucts32zg67has5skub3crja733ag5gy6x3lgq257mhbxs5ooi@jpeg)

It gets better. Because it is excreted in urine unchanged, penicillin was recycled from the urine of soldiers who were lucky enough to get some doses, and reused on other soldiers.

MW

Matt Wright

@mattwright.bsky.social

Restaurant owner in Austin, dad, hoops fan. Main interests: #rstats, data viz, Power BI, cheaper housing, Wem-V-P. (Not a frequent poster.)

165 followers598 following313 posts